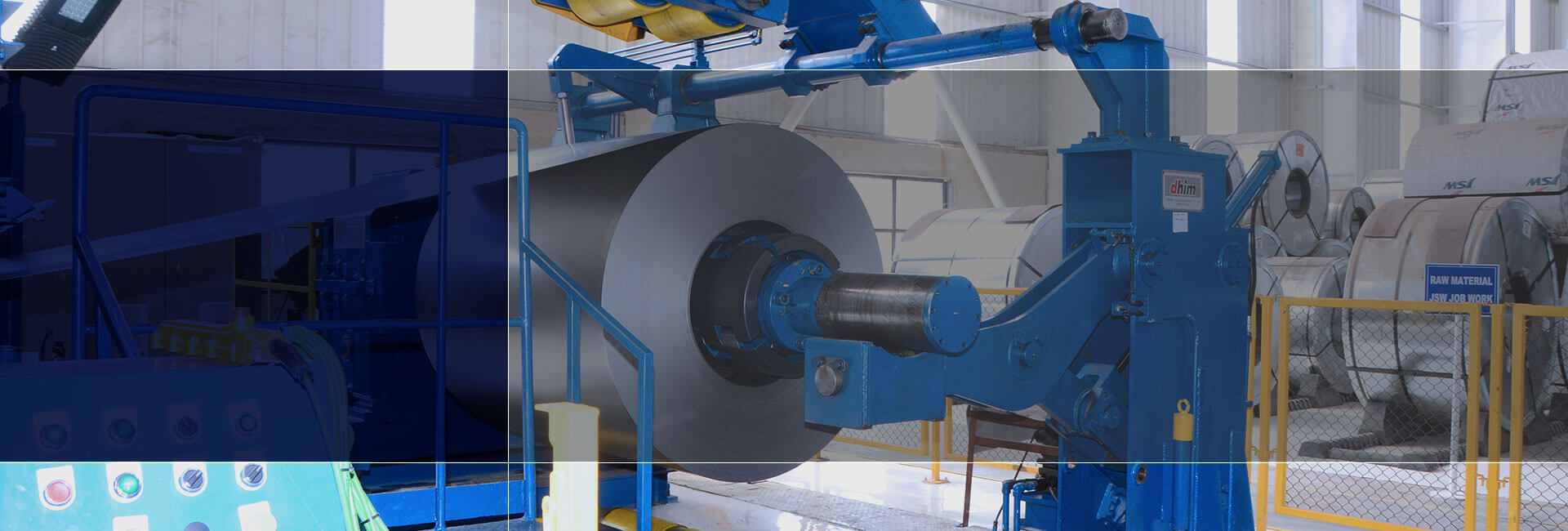

Cut to Length

Cut To Length is a process in which steel coils are uncoiled and fed through a shear blade for length wise cutting into required lengths with precise tolerances. Levellers and straighteners are installed after the uncoiler and before the shear for shape corrections and flattening of the sheets.